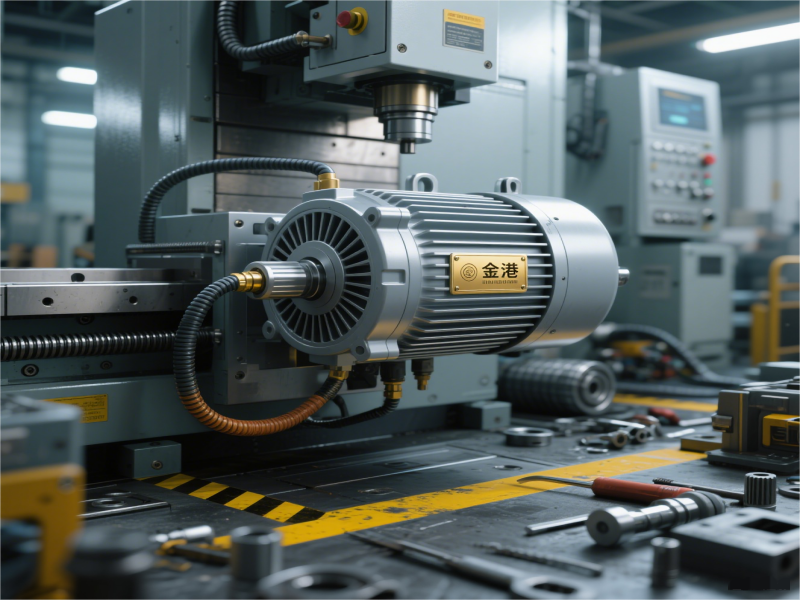

Application cases of vector motors in industrial automation

CNC machine tool processing:

In CNC lathes, milling machines, drilling machines and other equipment, vector motors are used for spindle drive and feed axis drive. For example, Siemens’ servo motor system is used in five-axis linkage machining centers, which achieves high-speed cutting through vector control, and the spindle speed can reach more than 10,000 rpm, while ensuring micron-level positioning accuracy, and can complete high-precision processing of complex parts such as aircraft engine blades.

Robots and robotic arms:

The millisecond-level torque response and precise torque control of vector motors enable robots to perform delicate movements such as welding and assembly. For example, on an automobile production line, robotic arms can use vector motors to precisely control movements, accurately install parts to designated locations, and can carry heavier parts to meet the high-intensity operation requirements in industrial production.

Textile machinery:

In spinning machines, vector motors are used to control the speed and tension of rollers. Through precise speed control, the yarn maintains stable tension during the spinning process, and the tension fluctuation can be controlled to ≤1%, effectively avoiding yarn breakage and improving yarn quality. In looms, vector motors control the main shaft and weft insertion mechanism of the loom to ensure the interweaving accuracy of warp and weft yarns, improving fabric quality and production efficiency.

Printing machinery:

Taking a multi-color printing press as an example, vector motors are used to control printing rollers and paper feeding mechanisms. After using a vector inverter, paper tension fluctuations can be reduced by 80%, and color registration accuracy is increased to ±0.05mm, ensuring accurate registration of printed patterns and improving the quality of printed products.

Packaging machinery:

In filling machines, vector motors control the movement of the filling head and the conveying of materials, achieving high-speed and precise filling operations. For example, after a filling machine applied vector motors, its production efficiency increased by 40%, and the product qualification rate increased to 99.9%. In labeling machines, vector motors accurately control the conveying and pasting position of labels, ensuring the accuracy and aesthetics of label pasting.

Cranes:

Port cranes use vector inverters to control vector motors to achieve precise hook positioning and heavy-load lifting. At low frequencies (such as 0.5Hz), they can output 150%-200% rated torque to ensure smooth startup of heavy-load equipment, avoid mechanical shock and overload tripping, and increase the crane’s operating efficiency by more than 30%.