Different application characteristics of three-phase motors and single-phase motors in material handling motors

1.Power supply mode and starting characteristics

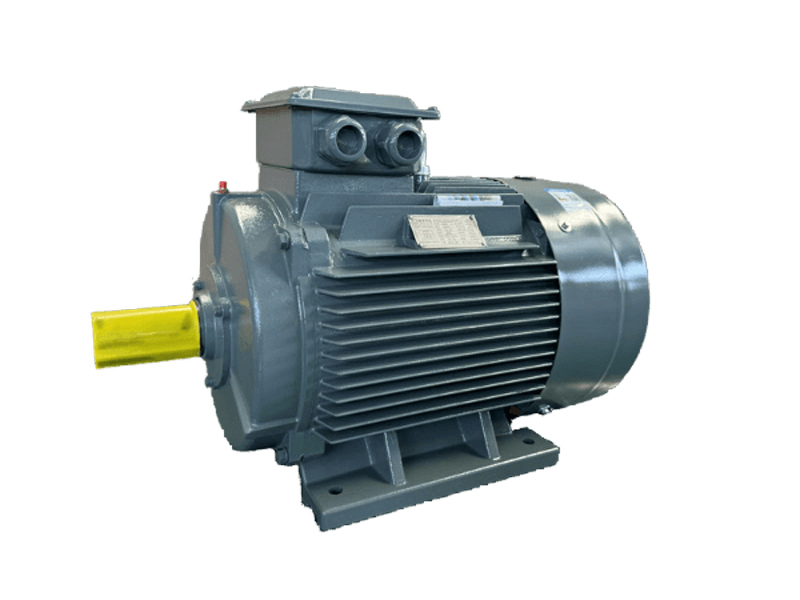

Three-phase asynchronous motor

Power supply: requires three-phase AC power supply (380V/220V), and high voltage balance is required.

Starting performance: Strong self-starting ability, no additional starting device is required (direct start or star-delta step-down start). Large starting torque (up to 1.5-2 times the rated torque), suitable for heavy-load starting (such as cranes, conveyor belts).

Efficiency: High efficiency (usually >85%), good power factor, suitable for long-term continuous operation.

Single-phase motor

Power supply: single-phase 220V power supply, suitable for home or small places.

Starting performance: No self-starting ability, additional starting winding, capacitor (such as capacitor starting, split-phase type) or centrifugal switch is required. Starting torque is small (capacitor starting can reach 2-3 times the rated torque, but generally still lower than three-phase motor), suitable for light load starting (such as small elevators, light conveyors).

Efficiency: low efficiency (usually <70%), poor power factor, easy to heat up after long-term operation.

2.Power and load capacity

Three-phase motor

Wide power range, suitable for medium and high power requirements (such as forklift drives, large conveying systems).

Strong load adjustment capability and good overload performance (overload capacity can reach 1.8-2.5 times rated torque).

Single-phase motor

Usually small power (<3KW), limited to low power scenarios (such as small electric hoists, packaging machines).

Weak overload capacity, continuous high load can easily lead to excessive temperature rise or even burnout.

3.Operation stability and speed regulation

Three-phase motor

Smooth operation, low vibration, low torque fluctuation.

Various speed regulation methods (variable frequency speed regulation, variable pole speed regulation), suitable for scenarios requiring precise speed control (such as automated assembly lines).

Single-phase motor

Large vibration and noise during operation, requiring additional shock absorption design.

Speed regulation is difficult, usually requiring voltage reduction or capacitor speed regulation, which further reduces efficiency.

4.Cost and maintenance

Three-phase motor

High manufacturing cost, but low energy consumption in long-term operation, better overall cost.

Simple maintenance (no capacitor or centrifugal switch), long life.

Single-phase motor

Low initial cost, suitable for small equipment with limited budget.

Complex maintenance (capacitor and starting device need to be checked regularly), high failure rate.

5.Typical application scenarios

Three-phase asynchronous motors

Heavy cranes, bucket elevators, large conveyor belts, electric forklifts, industrial compressors, etc.

Occasions requiring continuous operation and high reliability (such as port logistics, production lines).

Single-phase motors

Small household lifting platforms, light conveyor belts, warehouse electric carts, packaging equipment, etc.

Temporary or intermittent work (such as retail warehousing, small workshops).