Specific application scenarios of three-phase asynchronous motors in the mining industry

Three-phase asynchronous motors are widely used in various mining equipment in the mining industry due to their simple structure, low cost, easy maintenance, and adaptability to harsh environments.

Core equipment for mining production

1. Mine hoist

Application scenario: used to lift coal, ore, personnel and materials in mines, and is a key equipment for mine transportation.

Features:

High-power drive: It needs to match a three-phase asynchronous motor of hundreds to thousands of kilowatts to meet the requirements of heavy-load starting and continuous lifting.

Speed regulation and braking: Speed regulation through frequency converter or rotor series resistance, combined with mechanical braking system to achieve precise start and stop to ensure safety.

High reliability requirements: The motor needs to be moisture-proof, dust-proof, and vibration-resistant, and adapt to the humid and dusty environment underground.

2.Ventilator

Application scenario: Provide fresh air for mines, discharge harmful gases such as gas and dust, and ensure the safety of underground operations.

Features:

Continuous operation: The motor needs to operate 24 hours a day, with high efficiency and low temperature rise.

Explosion-proof design: Explosion-proof three-phase asynchronous motors are required in gas mines to avoid explosions caused by electric sparks.

Frequency conversion adjustment: The air volume is adjusted through frequency conversion technology to meet the ventilation needs of different mining stages, with significant energy-saving effects.

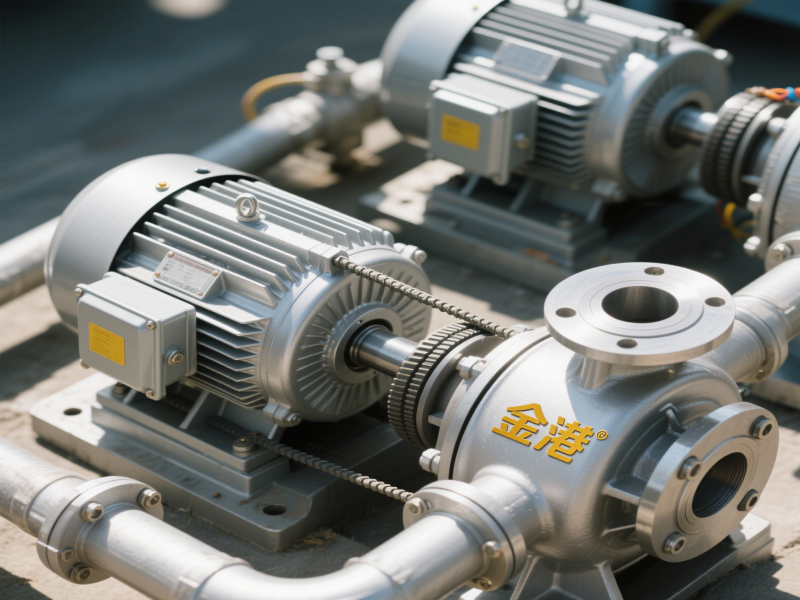

3.Drainage pump

Application scenario: remove water from mines, prevent water accidents, and ensure mining safety.

Features:

High head and large flow: The motor power is designed according to the depth of the mine and the amount of water inflow, usually tens to hundreds of kilowatts.

Waterproof and moisture-proof: The motor adopts a sealed structure and moisture-proof insulation materials to adapt to the humid environment underground.

Automatic control: Linked with the water level sensor to achieve automatic start and stop, reducing manual intervention.

Mining operation auxiliary equipment

1.Crusher and Grinding Machine

Application scenario: Crushing ore (such as jaw crusher, cone crusher) and grinding (such as ball mill) to prepare for the subsequent ore dressing process.

Features:

High torque starting: The motor needs to have a high starting torque (such as a wound asynchronous motor) to overcome the huge resistance during the initial operation of the equipment.

Wear resistance and heat dissipation: Due to the large vibration and heavy load of the equipment, the motor needs to strengthen the bearing and heat dissipation design to extend the service life.

2.Belt conveyor

Application scenario: It is used to transport ore, coal and other materials in mine tunnels, ground yards and other scenarios. It is the core equipment of mine logistics.

Features:

Multi-machine collaborative drive: Multiple motors are used for segmented drive during long-distance transportation, and load balancing is achieved through synchronous control.

Soft start technology: Soft start is achieved by using inverter or hydraulic coupling to reduce mechanical shock and extend belt life.

Dustproof and wear-resistant: The motor housing has a high protection level (such as IP55) and is suitable for dusty environments.

3.Rock drills and drilling equipment

Application scenarios: underground rock drilling and blasting (such as electric drive devices for pneumatic rock drills), geological exploration drilling, etc.

Features:

High speed and impact load: The motor needs to match the high-frequency impact requirements of the rock drill, and usually adopts a cage-type asynchronous motor with a sturdy and durable structure.

Miniaturization and portability: Some mobile equipment uses compact motors to facilitate operations in narrow underground spaces.

Open pit mining equipment

1.Excavators and electric shovels

Application scenarios: Excavating ore and stripping topsoil in open-pit mines, which are the main equipment for open-pit mining.

Features:

High power and high reliability: The motor power can reach thousands of kilowatts and needs to adapt to high temperature, dust and frequent start and stop in the open-pit environment.

Hydraulic drive coordination: The motor drives the hydraulic pump to provide power for the excavation arm, bucket and other actions, requiring stable speed and sensitive response.

2.Mobile crushing station

Application scenario: On-site crushing of ore in open-pit mines to reduce transportation costs.

Features:

Mobility and adaptability: The motor needs to adapt to the vibration and tilt of the equipment when it moves, and adopts a compact design and efficient cooling system.

Multi-motor linkage control: The motors in multiple links such as crushing and screening need to operate in a coordinated manner, and synchronized start and stop and load distribution are achieved through the control system.

Application in special mining scenarios

1.Gas extraction pump

Application scenario: Extracting gas from high-gas mines for power generation or safe discharge.

Features:

Explosion-proof and corrosion-resistant: Use explosion-proof asynchronous motors, and the motor materials must resist the corrosive components that gas may contain.

Constant power operation: The extraction pump needs to be driven stably to ensure that the gas concentration is controlled within a safe range.

2.Mine cable cars and ropeways

Application scenarios: Transporting personnel or materials in mines with complex terrain, such as inclined shaft cable cars, freight ropeways, etc.

Features:

Safety redundancy design: The motor is usually equipped with a backup power supply or dual motor drive to ensure uninterrupted transportation.

Precise speed regulation: The frequency conversion technology is used to achieve the switching between low-speed smooth start and high-speed operation, ensuring the comfort of personnel and the stability of material transportation.

Summary of the advantages of three-phase asynchronous motors in mining

Low cost: simple structure: mature manufacturing process, initial purchase cost is lower than synchronous motor or DC motor.

Convenient maintenance: no commutator and brush, less maintenance workload, suitable for scenes with insufficient maintenance personnel at mining sites.

Strong environmental adaptability: can be adapted to harsh environments such as humidity, dust, flammable and explosive underground through explosion-proof, waterproof, dust-proof and other modifications.

High reliability: stable operation, shock and vibration resistance, suitable for the needs of long-term heavy-load operation of mining equipment.

Great energy-saving potential: with frequency conversion technology, the speed can be adjusted in real time according to the load to reduce idling loss, especially suitable for variable load scenes such as ventilation and drainage.

Three-phase asynchronous motors cover the entire process from mining, transportation to safety assurance in the mining industry. Their technical characteristics are deeply compatible with mining scenarios, making them the core power source of mining equipment.