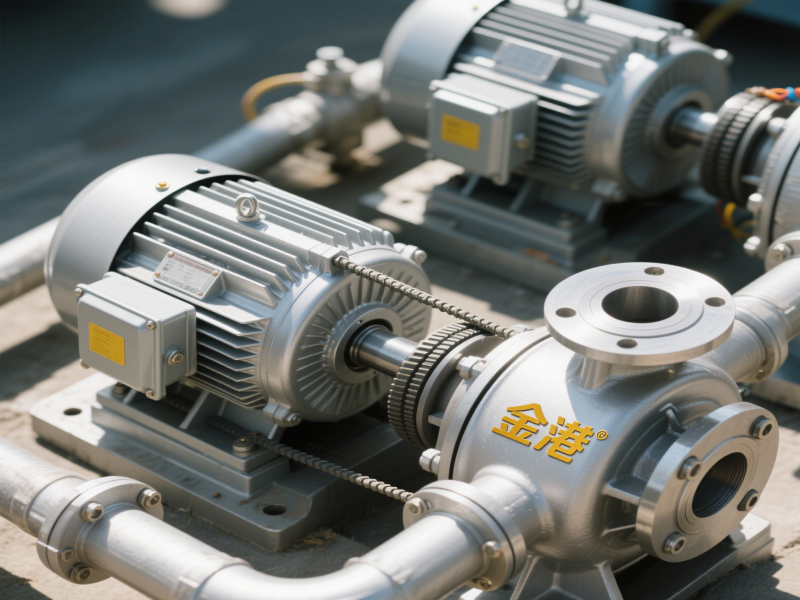

Application advantages and scenarios of three-phase asynchronous motors in pump motors

Advantages of three-phase asynchronous motors in pump motors

1.Simple structure and high reliability

Design features: no commutator and brushes, the rotor is a cage structure (copper bars or aluminum bars embedded in the iron core), and the mechanical structure is simple and compact.

Advantages:

Low failure rate, less maintenance requirements, suitable for long-term continuous operation (such as industrial water supply and drainage, agricultural irrigation, etc.).

Strong resistance to shock and vibration, adapted to the mechanical load characteristics of pump equipment.

2.Low cost and good economy

Manufacturing and maintenance costs: The simplified structure reduces the difficulty of production and material costs, and does not require a complex control system (such as an inverter for a DC motor).

Applicable scenarios: It has significant advantages in cost-sensitive small and medium-sized pump systems (such as household booster pumps and ordinary industrial circulation pumps).

3.High efficiency and energy saving, strong adaptability

Efficiency characteristics: The efficiency is high near the rated speed (usually 80%~95%), and the energy consumption under different working conditions can be further optimized with variable frequency speed regulation technology (such as inverter).

Speed matching: The synchronous speed is determined by the power supply frequency and the number of motor poles (n0=p60f), and the speed requirements of the water pump can be directly matched by selecting the number of poles (2 poles, 4 poles, 6 poles, etc.) (e.g. centrifugal pumps usually require high speeds, and positive displacement pumps require low speeds).

4.Easy to start, adapt to a variety of power sources

Direct starting capability: small and medium-sized three-phase asynchronous motors can be started directly without additional starting equipment (large motors need to be started at reduced voltage to reduce impact).

Power supply compatibility: Applicable to three-phase industrial frequency power supply (such as 380V/50Hz), good compatibility with industrial power grid, no special power conversion device required.

5.Improved speed regulation performance (combined with frequency conversion technology)

Traditional limitations: The speed regulation of asynchronous motors needs to be changed by changing the power supply frequency, number of poles or slip rate, and the traditional adjustment range is limited.

Modern optimization: After being combined with a frequency converter, a wide range of stepless speed regulation can be achieved, and the flow and pressure of the pump can be accurately controlled (such as constant pressure water supply system, water pump speed regulation in sewage treatment plants), while reducing the starting current and mechanical shock.

Typical application scenarios of three-phase asynchronous motors in pumps

1.Industrial field

Chemical and petroleum industry: centrifugal pumps and gear pumps for conveying corrosive liquids (such as acid and alkali solutions) require motors to be explosion-proof (such as flameproof asynchronous motors) and resistant to medium corrosion.

Metallurgy and mining: mine drainage pumps and slurry conveying pumps require motors to adapt to high-load and dusty environments and have high reliability and overload capacity.

Power industry: power station circulating water pumps and condensing pumps, used in cooling systems or steam circulation, require motors to operate stably for a long time and have high efficiency (such as high-voltage asynchronous motors).

2.Civil and construction fields

Water supply system: high-rise building booster pumps and community secondary water supply pumps, with variable frequency technology to achieve constant pressure water supply, with significant energy saving effect.

Drainage and sewage treatment: sewage lifting pumps and aeration tank mixing pumps, the motors need to be moisture-resistant and anti-clogging, and some scenes need to be explosion-proof (such as the flammable and explosive environment of sewage treatment plants).

Air conditioning and HVAC: Central air conditioning chilled water pumps and cooling water pumps, adjust the water flow through variable frequency speed regulation, match the changes in air conditioning load, and reduce energy consumption.

3.Agriculture and water conservancy

Irrigation and drainage: farmland sprinkler pumps and drainage pumps require motors that are resistant to mud and sand, overload, and suitable for outdoor environments (such as three-phase asynchronous motors with diesel engines as backup power sources).

Agricultural processing: grain delivery pumps and oil press matching pumps require motors with low speed and high torque to adapt to intermittent working modes.

Shipbuilding and marine engineering: Ship cooling water pumps and ballast water pumps require motors that are resistant to salt spray corrosion and vibration and meet ship specifications (such as marine asynchronous motors).

Aerospace ground equipment: Aircraft ground refueling pumps and hydraulic system pumps require motors that are small in size, light in weight, and highly reliable.

Comparison with other motor types

| Motor Type | Advantages | Pump application limitations |

| Three-phase asynchronous motor | Low cost, simple structure, resistant to harsh environment | The speed regulation accuracy is low (frequency conversion is required) |

| DC Motor | Accurate speed regulation and large starting torque | High cost and complex maintenance (brush is easy to wear) |

| Permanent magnet synchronous motor | High efficiency, high power factor, good speed regulation performance | High cost and high control requirements |

| Stepper Motor | Extremely high control accuracy (suitable for micro-flow scenarios) | Low power, poor high-speed performance |

Summary

Three-phase asynchronous motors have become the mainstream power choice for pump equipment due to their simple structure, low cost and high reliability, and are especially irreplaceable in medium and large power scenarios in industry, civil and agriculture. When choosing, it is necessary to match the motor type (such as ordinary type, explosion-proof type, submersible type) and control method according to the specific working conditions (such as medium characteristics, speed requirements, and environmental conditions) to achieve the best performance.