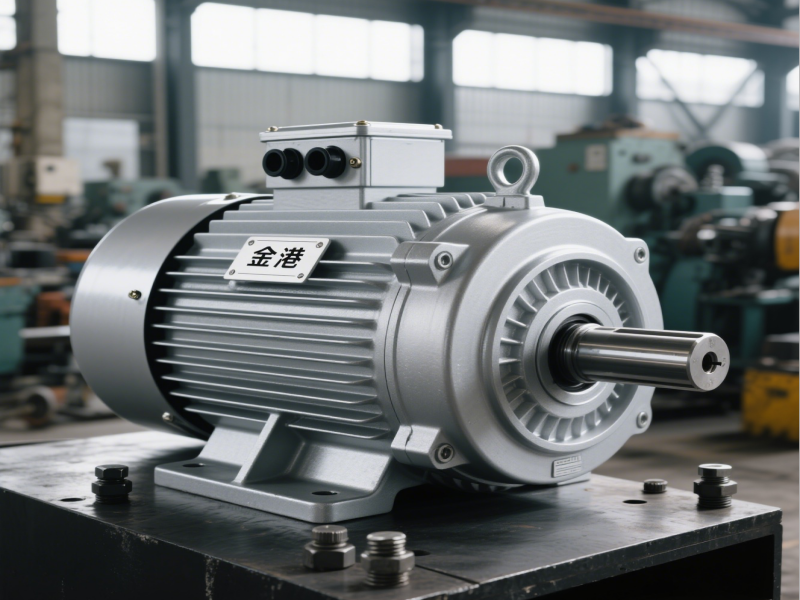

Introduction of cast iron motor

Introduction

Cast iron motor refers to a motor whose housing is mainly made of cast iron. Cast iron has high hardness and strength, can withstand large external forces and pressures, and provides reliable protection for the windings, iron cores and other components inside the motor.

Characteristics

1. Advantages

(1) High hardness and strong pressure resistance: The cast iron housing has high hardness, strong resistance to external pressure, and is not easy to deform. It can effectively protect the windings, iron cores and other components inside the motor. It is suitable for some occasions with large driving force and large vibration during work, such as mining machinery and heavy machine tools.

(2) Low price: Compared with some motors with special alloys or high-quality steel housings, cast iron motors have lower costs and are relatively cheap. They have great advantages in some application scenarios with strict cost control.

(3) Strong adaptability: It can work in harsh environmental conditions such as high temperature, humidity, and dust, and has good environmental adaptability. For example, it can operate stably in harsh working environments in industries such as metallurgy, casting, and cement.

2. Disadvantages

(1) Heavy weight: The density of cast iron is relatively high, which makes cast iron motors relatively heavy. They may not be suitable for some equipment that requires lightweight design, such as some portable equipment or aerospace fields that have strict weight requirements.

(2) Poor thermal conductivity: The thermal conductivity of cast iron is not as good as that of metals such as aluminum. The heat generated during the operation of the motor is not easy to dissipate, which can easily cause the internal temperature of the motor to rise, affecting the performance and service life of the motor. Additional cooling measures are required.

(3) Limited processing performance: It cannot be die-casted, and its plasticity and elongation are poor, which makes the design and manufacturing of the shell of cast iron motors subject to certain restrictions, and it is difficult to make parts with complex shapes.

(4) High noise: The noise generated during operation is relatively high, which may cause certain noise pollution to the working environment. Sound insulation or noise reduction measures need to be taken.

Application areas

- Industrial production: It is widely used in various industrial production equipment, such as fans, water pumps, compressors, conveyors, etc. These equipment usually require large driving force and high reliability. Cast iron motors can meet their working requirements.

- Mining machinery: Various mechanical equipment used in mining and processing, such as crushers, ball mills, hoists, etc., have harsh working environments and heavy loads. The durability of cast iron motors makes them an ideal choice for these equipment.

- Construction: Mixers, cranes, concrete pumps and other equipment on construction sites also often use cast iron motors to adapt to high-intensity work and complex construction environments.