Specific applications of IE3 grinder motors

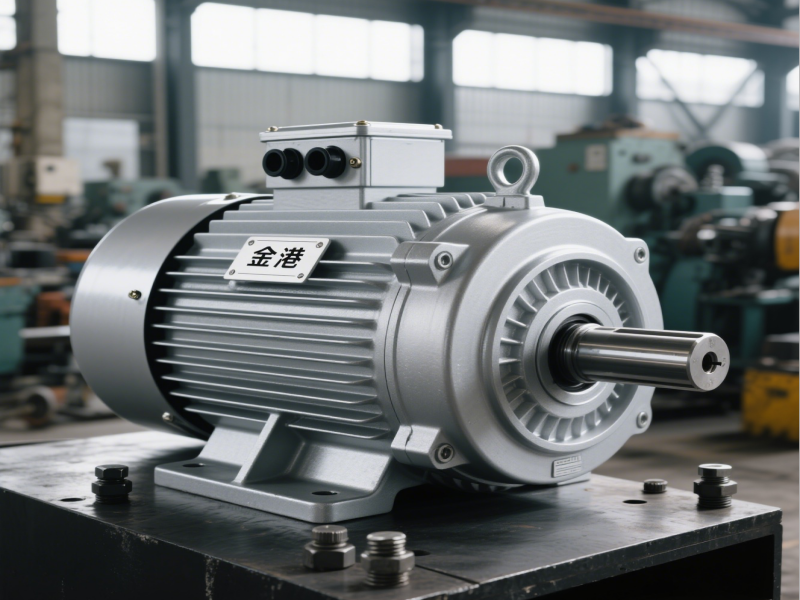

As efficient and stable power equipment, the three-phase asynchronous IE3 grinder motor has a wide range of key applications in metal processing, machinery manufacturing and other fields, thanks to its IE3 energy efficiency level (international level 3 energy efficiency standard) and its adaptability to grinder working conditions. Its specific application scenarios can be divided into the following categories according to the type of grinder and processing requirements:

General Grinding Equipment: The “Main Power” of Basic Processing

Cylindrical Grinding Machine

Cylindrical grinding machines are used to grind the outer surfaces of shafts and cylindrical workpieces, and have high requirements for the motor’s speed stability and output torque. The IE3 grinder motor uses a stable rotating magnetic field and low slip characteristics to ensure that the grinding head (grinding wheel) speed fluctuation is controlled within ±1%, avoiding ripples or precision deviations on the workpiece surface due to unstable speed. For example, in the grinding of automotive drive shafts, the IE3 motor can cooperate with the feed system to achieve 0.001mm surface roughness (Ra≤0.8μm) processing, while the high energy efficiency reduces the energy consumption cost of long-term mass production.

Surface grinder

Surface grinders need to grind workpiece planes with high precision (such as mold templates and machine tool guide surfaces). The reciprocating or rotating motion of the grinding head depends on the forward and reverse flexibility of the motor. The IE3 motor supports fast forward and reverse switching (response time ≤ 0.5 seconds) through optimized stator winding design, and the starting current is only 5-7 times the rated current (traditional motors are mostly 7-10 times), reducing the impact on the workshop power grid. In the surface grinding of precision measuring tools (such as vernier calipers), its stable output can ensure that the parallelism error of the workpiece is ≤ 0.002mm/100mm.

Precision and special grinders: the “core driver” of high-demand processing

Tool grinders

Tool grinders are used to grind the cutting edge and shape of cutting tools (such as milling cutters, drills, and taps), and require motors to support a wide range of speed regulation (usually 500-3000r/min). After the IE3 grinder motor is equipped with a variable frequency speed regulation system, the speed can be accurately adjusted by changing the power supply frequency. For example, 2000r/min is used when grinding high-speed steel drills, and 3000r/min is switched when grinding carbide milling cutters. The efficiency is maintained above 85% during the speed regulation process (the efficiency of ordinary motors may drop by 10%-15% during speed regulation), taking into account both precision and energy consumption.

Centerless grinders

Centerless grinders grind cylindrical workpieces (such as bearing rollers and pins) through the cooperation of grinding wheels and guide wheels, and have strict requirements on the continuous load capacity of the motor (need to run continuously for 8-12 hours). IE3 motors have lower copper and iron losses, and the temperature rise during operation is 10-15℃ lower than that of IE2 motors (maximum temperature ≤80℃), which reduces downtime maintenance caused by overheating. In batch grinding in the bearing industry, it can increase the equipment utilization rate by 5%-8%.

Internal grinding machine

Internal grinding machines are used to grind the inner holes of workpieces (such as hydraulic cylinders and gear inner holes). Due to the limited processing space, the motor must have a compact structure and low vibration characteristics. The IE3 grinder motor optimizes the rotor dynamic balance (balance accuracy reaches G2.5 level) and adopts silent bearings, with an operating noise of ≤75dB (A), avoiding vibration transmission to the grinding wheel and increasing the roundness error of the inner hole. In the grinding of the inner hole of hydraulic components, precision machining with a roundness of ≤0.001mm can be achieved.

Grinding under special working conditions: “Reliable guarantee” for harsh environments

Wet grinding scenarios

In most grinding machine processes, coolant (emulsion or cutting oil) is required to wash away debris, and the motor must be able to prevent liquid intrusion. IE3 grinder motors usually use IP55 protection level (dustproof + low-pressure water jet protection), and the stator winding is impregnated to form a moisture-proof insulation layer. It can operate stably for a long time even in an environment with coolant splashing. For example, in wet grinding of automobile gearbox housings, the motor’s mean time between failures (MTBF) can reach more than 10,000 hours.

Heavy-duty grinding equipment

Heavy-duty grinders (such as guide rail grinders and roll grinders) are used to grind large workpieces (such as machine tool beds and rolling mill rolls), and require motors to provide large torque output (usually 50-200N・m). IE3 motors can maintain high torque at low speeds (starting torque can reach 2.5 times the rated torque) by thickening the rotor conductor and optimizing the magnetic circuit design, meeting the “slow grinding, high feed” requirements of heavy workpieces. At the same time, the high-efficiency characteristics reduce the operating electricity costs of high-power equipment (such as motors above 15kW), and annual electricity savings can reach tens of thousands of yuan.

Industry Application: From Basic Manufacturing to High-end Precision

Automotive Manufacturing: Used for engine crankshaft grinding and gearbox gear shaft grinding to ensure the matching accuracy of parts.

Aerospace: Provide stable power to meet the stringent dimensional tolerance requirements (±0.005mm) in the precision grinding of turbine blades and aircraft structural parts.

Bearing and Hydraulic Industry: High-precision grinding of bearing rollers and hydraulic pump plungers is a key link to ensure mechanical transmission efficiency.

Mold Processing: In the cavity grinding of plastic molds and stamping molds, speed adjustment is used to adapt to the grinding requirements of materials with different hardness (such as mold steel and cemented carbide).

Summary

The core of the application of three-phase asynchronous IE3 grinder motors is: based on high efficiency and energy saving, with stable output as the core, and with adapting to grinding conditions as the goal. Whether it is mass production of general grinding, micron-level requirements of precision machining, or long-term operation in harsh environments, its performance can meet the triple needs of grinders for “precision, efficiency, and reliability”, becoming an indispensable power equipment in modern metal processing. With the improvement of industrial energy efficiency standards, IE3 motors are gradually replacing low-efficiency motors and becoming the mainstream configuration of grinding equipment.