Introduction and advantages of IE3 grinder motor

Introduction

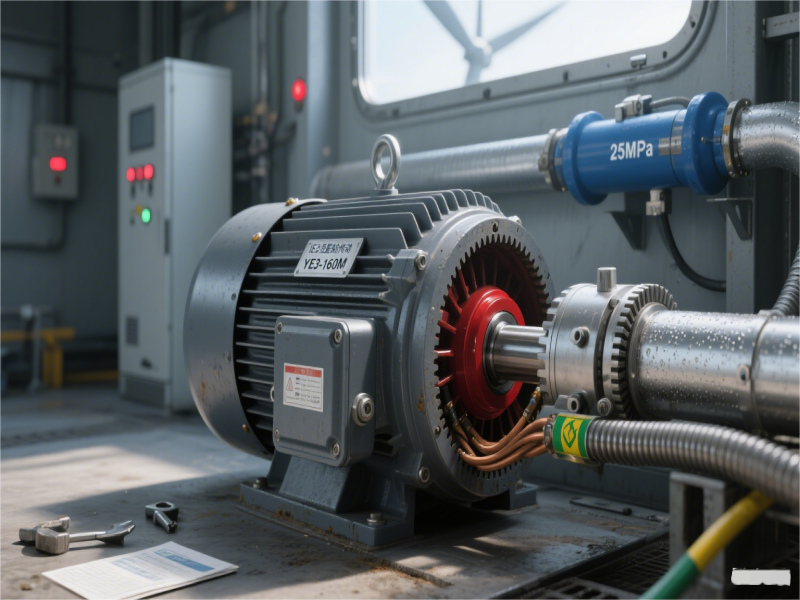

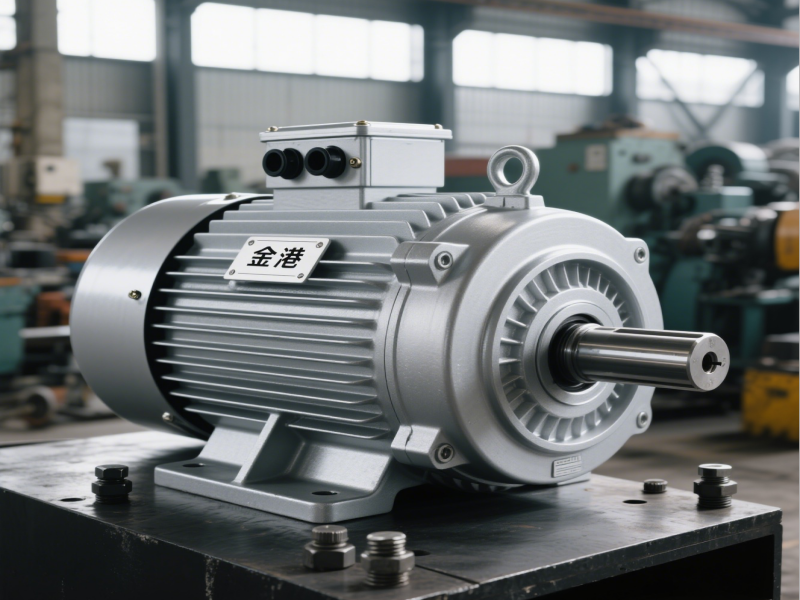

IE3 Grinder Motors are usually fully enclosed fan-cooled (TEFC) structures, which can effectively prevent dust, water droplets, etc. from entering the motor interior, improving the reliability and service life of the motor. The motor housing is generally made of cast iron, which has good strength and heat dissipation performance, and the terminal box can be made of steel plate.

Advantages

1.Significant energy saving effect

a. High-efficiency conversion:Henan Jingang Motor adopts a new winding design and low-loss silicon steel sheet materials, which effectively reduces the copper loss and iron loss during motor operation, improves the power conversion efficiency, and can significantly reduce power consumption compared to motors with lower energy efficiency levels.

b. Reduce energy consumption costs: For grinding equipment that runs for a long time, IE3 grinding motors can significantly reduce electricity bills and save operating costs for enterprises.

2. Reliable and stable performance

a.High-quality materials and processes: During the manufacturing process, high-quality materials and advanced production processes are used to ensure that all components of the motor have good performance and reliability. For example, the motor’s bearings, windings and other key components are carefully designed and manufactured to withstand long-term operating loads.

b.Strict quality inspection: Following strict quality inspection standards, the motor is subjected to multiple performance tests, such as insulation test, withstand voltage test, efficiency test, etc., to ensure that each motor can meet high quality requirements, reduce the probability of motor failure during operation, and improve the overall operation stability of the equipment.

a. Low loss and low heat generation:Due to the high efficiency of the motor, the heat generated during operation is relatively small, which reduces the aging speed of various motor components, especially the damage to vulnerable parts such as winding insulation and bearings, thereby extending the service life of the motor.

b. Good heat dissipation design:Henan Jingang Motor adopts a fully enclosed fan-cooled structure and optimized heat dissipation design, so that the motor can dissipate heat in time during operation, maintain a low operating temperature, and further extend the service life of the motor.

c. Wide range of applications:IE3 Grinder Motors are suitable for various industrial fields that require grinding operations, such as ore grinding, cement grinding, coal powder grinding and other equipment in mining, metallurgy, building materials, chemical industry, power and other industries. It can also be used in some commercial and industrial applications with high requirements for motor energy efficiency and performance, such as grinding equipment in food processing, pharmaceuticals, papermaking and other industries.

d. Environmentally friendly: The IE3 Grinder Motors manufactured by Henan Jingang Motor meet international and domestic energy efficiency standards, which helps companies meet environmental requirements, reduce carbon emissions, and enhance the company’s social image.