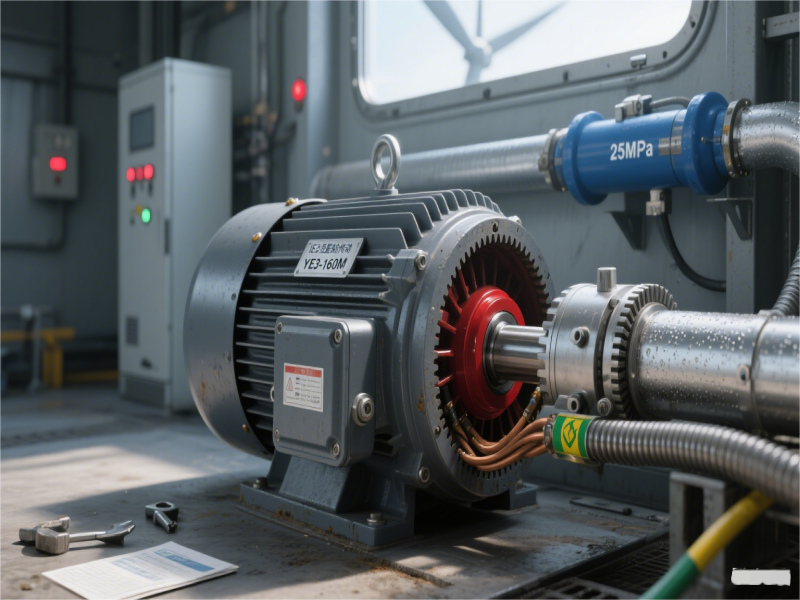

The difference between IE3 three-phase asynchronous motor and single-phase motor in wind turbine application

The differences between IE3 three-phase asynchronous motors and single-phase motors in wind turbine applications stem primarily from differences in their structural characteristics, power ranges, energy efficiency, and applicable scenarios. This is particularly evident in different wind turbine systems (such as auxiliary drives and small units). The following comparative analysis focuses on key dimensions:

Power Range and Applicable Scenarios

The core requirement of wind turbines is stable drive systems (such as yaw, pitch control, cooling, hydraulics, etc.) or the power output of small units. Power requirements range from hundreds of watts to tens of kilowatts. The difference in power coverage directly determines the differentiation of application scenarios:

IE3 three-phase asynchronous motors:

The power range is generally 0.75kW to 630kW, covering the vast majority of auxiliary system requirements in wind turbines (such as 10kW to 50kW yaw drive motors and 5kW to 20kW pitch motors). They can even be used in small distributed wind power (such as the main drive and auxiliary systems of units under 100kW).

They are suitable for auxiliary drive systems of medium-to-large wind turbines (onshore/offshore, power ≥1MW) or core power systems of small wind turbines.

Single-phase motors:

Power is typically limited to 0.1kW to 3kW, meeting only very low power requirements, such as cooling fans for small wind turbines (≤10kW), small hydraulic pumps, or auxiliary equipment for off-grid micro-wind turbines (e.g., household units under 500W).

They are suitable for micro/small wind turbines (≤10kW), often used in off-grid scenarios (such as power supply in remote areas and RVs).

Energy Efficiency and Environmental Protection Requirements

As clean energy devices, wind turbines strictly control their energy consumption, and energy efficiency rating is a key consideration:

IE3 three-phase asynchronous motors:

Comply with international energy efficiency standards (IE3 stands for “high efficiency,” corresponding to Level 2 efficiency in China’s GB18613-2020 standard). Their energy efficiency ratio (η) typically ranges from 85% to 95% (depending on power), significantly exceeding that of conventional motors.

During long-term operation of wind turbines (over 2,000 hours of annual operation), they can significantly reduce energy consumption in auxiliary systems, indirectly improving overall turbine efficiency and meeting the global wind power industry’s “lifecycle low-carbon” requirements (such as the EU Energy Efficiency Directive’s mandatory energy efficiency requirements for auxiliary equipment in wind turbines).

Single-phase motors:

Their energy efficiency ratings are generally lower (mostly IE1 or unspecified), with an energy efficiency ratio typically ranging from 60% to 80%. There is no unified high-efficiency standard (some small single-phase motors are not even included in the international energy efficiency system). It can only meet the basic energy consumption needs of micro wind power and cannot adapt to the energy efficiency policies of medium and large wind power projects (such as the mandatory energy efficiency certification requirements for wind power auxiliary equipment under China’s “dual carbon” goals).

Operational Stability and Reliability

Wind turbines must operate continuously in harsh environments (high and low temperatures, high humidity, salt spray, and strong vibration). The stability of the motor directly impacts the lifespan of the entire unit.

IE3 Three-Phase Asynchronous Motor:

Three-phase balanced power supply: Uniform current distribution results in low vibration and heat generation during operation, and more uniform bearing and winding losses. This makes it suitable for long-term, high-load operation (e.g., the yaw motor requires frequent starts and stops to adjust the nacelle’s orientation, and the pitch motor requires precise blade angle control).

Structural Strength: Typically, cast iron or cast aluminum housings are used with IP55/IP66 protection ratings (dust and water resistant). Combined with H-class insulation materials, these motors can withstand extreme temperatures ranging from -40°C to +60°C (e.g., in Nordic onshore wind power plants or tropical offshore wind power plants).

Starting Performance: High starting torque (typically 1.5 to 2.5 times the rated torque) allows them to directly drive loaded equipment (e.g., the yaw system’s gearbox) without the need for additional starting devices.

Single-Phase Motors:

Unbalanced single-phase power supply: A “pulsating magnetic field” creates high vibration and noise during operation, leading to concentrated heat. Long-term operation can easily lead to localized overheating and winding burnout (especially in the enclosed nacelle of a wind turbine, where heat dissipation is poor).

Structural Limitations: These motors typically feature small plastic or light metal housings with an IP rating below IP44, making them inadequate for withstanding salt spray and dust (as in desert or offshore wind power applications).

Low Starting Torque: Starting with a capacitor is typically required, resulting in a starting torque of only 0.5 to 1 times the rated torque. This makes them incapable of driving load-bearing equipment within the wind turbine (such as the screw drive mechanism of the pitch control system), and can easily lead to downtime due to starting failure.

Power Supply Compatibility and System Integration

The electrical system design of a wind turbine must be compatible with the grid or energy storage system, and the power supply compatibility between the two differs significantly:

IE3 three-phase asynchronous motors:

Directly adapt to the wind turbine’s three-phase power supply system (the wind turbine’s converter output is mostly three-phase AC with a voltage level of 380V/690V), eliminating the need for additional conversion equipment and simplifying system integration (for example, direct control of motor speed and direction via a PLC).

For grid-connected wind power projects, they can be directly connected to the grid’s three-phase distribution system, avoiding grid imbalances caused by single-phase power supply (large-scale wind power projects using a large number of single-phase devices can cause excessive grid harmonics).

Single-phase motors:

Requires single-phase power supply (such as converting from three-phase to single-phase using a converter, or directly inverting DC power from energy storage batteries into single-phase), increasing the cost and energy consumption of conversion equipment (conversion efficiency is typically 80%-90%). It is only suitable for off-grid micro wind power (such as using battery energy storage and inverter to 220V single-phase electricity). If it is connected to a three-phase power grid, an additional balancing device is required, otherwise it may affect the stability of the power grid.

Summary:

IE3 three-phase asynchronous motors, with their high power, high efficiency, high reliability, and compatibility with three-phase power supply, have become a core choice for auxiliary systems in medium- and large-scale wind turbines. Single-phase motors, however, are limited in power, efficiency, and stability to low-power auxiliary equipment in micro-off-grid wind turbines. As the wind power industry evolves towards higher power and higher efficiency, the use of IE3 three-phase asynchronous motors will continue to dominate, while the application of single-phase motors will continue to shrink.