What are the advantages of IE3 wind turbine motors?

Introduction

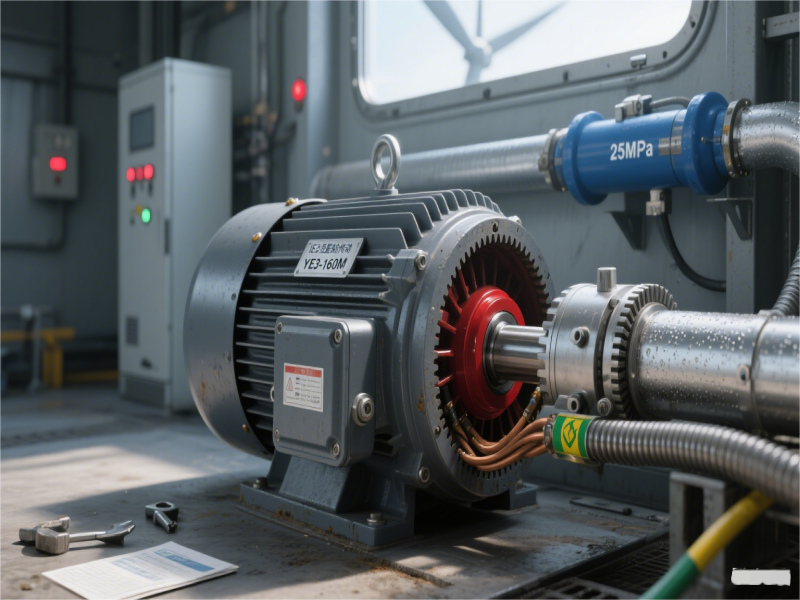

IE3 wind turbine motors are typically asynchronous, low-voltage, three-phase, totally enclosed fan-cooled (TEFC) motors.

Advantages

High Efficiency and Energy Saving: IE3 motors offer higher energy efficiency than IE1 motors, converting more electrical energy into mechanical energy and reducing energy loss. Henan JINGANG Motor’s YVF2 series motors are IE3-rated motors. Under the same power rating, they offer over 10% higher efficiency than standard motors, saving over 3,000 kWh annually.

Stable and Reliable Operation: These motors withstand harsh environments such as high humidity, corrosive salts, and fluctuating temperatures. Their mechanical design is designed to withstand the vibrations inherent in wind turbines, and they feature specialized windings that meet demanding grid requirements, making them suitable for long-term, stable operation in wind power generation scenarios.

Excellent Speed Regulation: IE3 motors are compatible with variable speed drive systems, enabling variable speed control. They can precisely adjust motor speed based on wind speed, improving wind turbine efficiency and adaptability to varying wind speeds. This also helps optimize process control and energy savings. Low Noise: IE3 motors typically utilize a closed-loop design, resulting in low noise levels during operation and minimizing noise pollution to the surrounding wind farm environment.

Applications

Wind Power Generation: IE3 wind turbine motors are primarily used in wind power generation. They can be installed in onshore or offshore wind farms, powering wind turbines and converting wind energy into mechanical energy, which is then converted into electrical energy.

Small Hydropower Stations: Due to their excellent performance and reliability, JINGANG motors can also be used in renewable energy generation applications requiring high motor efficiency and stability, such as in auxiliary power systems for small hydropower stations.